For every manufacturing challenge

there's an

UK & Offshore Assembly

To further enhance the Orbit service level, a dedicated UK based manufacturing facility in the Midlands is now able to support quick turnaround one-off prototypes through to, quick turnaround small / medium volume requirements.

UK Facilities

Our UK

0

sq. ft facilities:

- Fully automated SMT line

- Electrical testing for each component

- One off prototypes or medium batch runs

- Automatic optical inspection of paste application

- Temperature profiling hot air reflow oven

- Volume electrical and electro-mechanical assembly benches & workshop

- Manual soldering QFP rework station

- Functional testing equipment

- Wire preparation / Automatic wire cutter stripper

- 3 x automatic stripper, crimping machines

- Hand & pneumatic operated crimping tools

- Wire marking systems

- PAT testing

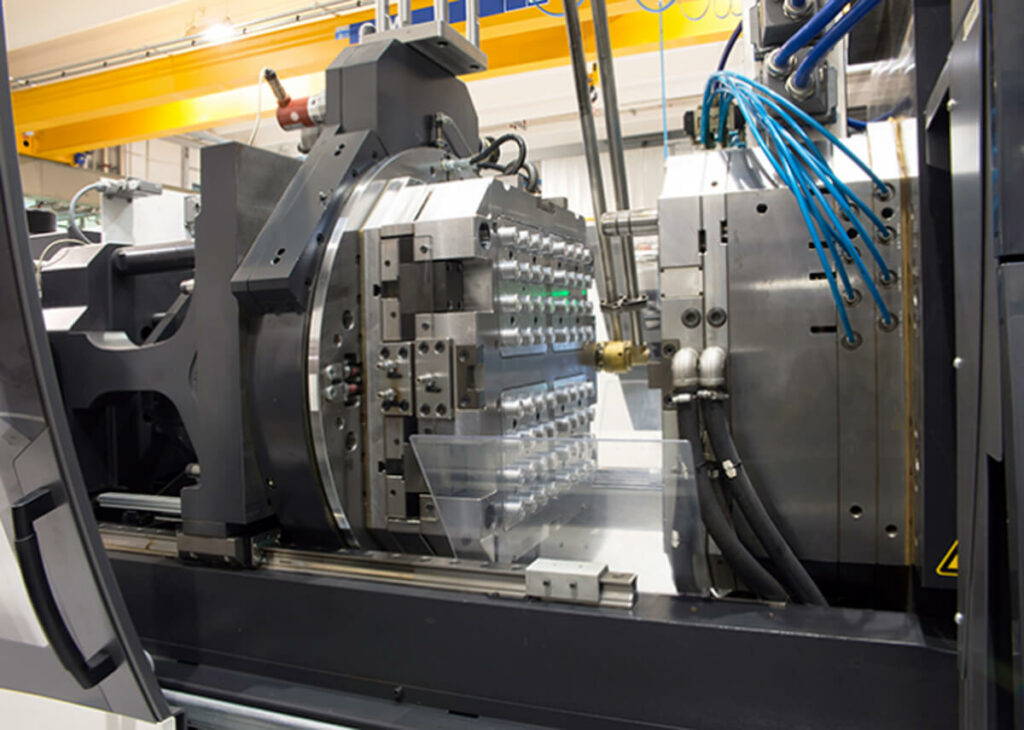

- Rapid prototyping equipment: CNC micro milling & engraving

- 3D printers

- Vacuum forming abilities

- Sheet metal press brake, linisher, grinding, pillar drills, fly press

- Multi-channel storage scopes, PSU’s, frequency generators, ESD test equipment

- Neutrik analysers, force gauges

- Storage & distribution, forklift / pallet truck

Offshore Facilities

Our offshore

0

sq. ft facilities:

- ISO accredited

- Over 450 assembly operators

- 6 final assembly production lines

- Full ODM services with 15 on-site engineers

- ISO 9001:2015 / ISO14001:2015 /ISO13485:2016 / IATF16949:2016 accredited company

- 13 fully automated SMT production lines including optical inspection on each

- 8 PTH semi-automated / hand assembly production lines

- BGA assembly including full X/Ray and re-work ability

- 3rd party CSR inspection carried out and pass obtained

- Service more than 60 overseas customers in total

- Approved and maintained component supply chain